PIC Tutorial - Stepper Board

Stepper Board

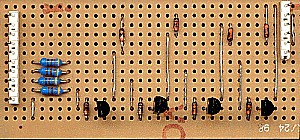

![]() This is

the Stepper Board, it contains four transistor drivers for feeding a uni-polar

stepper motor, such as those commonly found in old 5.25 inch floppy drives

and printers. The transistors are fed via 470 ohm resistors, to limit the

base current, and the eight diodes are there to absorb the back EMF (Electro

Motive Force) from the stepper motor coils when they turn off - when you

turn an inductor off, be it a motor or relay, it generates a high reverse

voltage spike (which is how car ignition coils work) - this would be likely

to damage the transistors, the diodes prevent it. The stepper motor itself

consists of two centre-tapped windings, with the centre-taps connected to

the positive supply rail, to make the motor move you need to activate the

coils in a certain sequence, it then moves one step for each value in the

sequence - a half-stepping mode is also available, which gives double the

number of steps by using a slightly different sequence. The wiring of the 6

pin connector to the motor is how the two motors I have are wired, one was

from an old floppy, the other is an Epson printer motor - both are wired the

same way on similar 6 pin connectors - not all motors are likely to be wired

exactly the same though!. I've marked the connections to the motor as A, B,

C and D, plus two marked '+', these are connected to the positive supply,

and to make the motor step the other four are grounded in a particular

sequence. The simplest sequence is to select them one at a time, A, B, C

then D, this produces 4 steps in a clockwise direction - to produce one full

rotation this needs to be repeated 50 times as my particular motor has 200

steps per revolution, giving 1.8 degrees resolution (in full step mode).

This is

the Stepper Board, it contains four transistor drivers for feeding a uni-polar

stepper motor, such as those commonly found in old 5.25 inch floppy drives

and printers. The transistors are fed via 470 ohm resistors, to limit the

base current, and the eight diodes are there to absorb the back EMF (Electro

Motive Force) from the stepper motor coils when they turn off - when you

turn an inductor off, be it a motor or relay, it generates a high reverse

voltage spike (which is how car ignition coils work) - this would be likely

to damage the transistors, the diodes prevent it. The stepper motor itself

consists of two centre-tapped windings, with the centre-taps connected to

the positive supply rail, to make the motor move you need to activate the

coils in a certain sequence, it then moves one step for each value in the

sequence - a half-stepping mode is also available, which gives double the

number of steps by using a slightly different sequence. The wiring of the 6

pin connector to the motor is how the two motors I have are wired, one was

from an old floppy, the other is an Epson printer motor - both are wired the

same way on similar 6 pin connectors - not all motors are likely to be wired

exactly the same though!. I've marked the connections to the motor as A, B,

C and D, plus two marked '+', these are connected to the positive supply,

and to make the motor step the other four are grounded in a particular

sequence. The simplest sequence is to select them one at a time, A, B, C

then D, this produces 4 steps in a clockwise direction - to produce one full

rotation this needs to be repeated 50 times as my particular motor has 200

steps per revolution, giving 1.8 degrees resolution (in full step mode).

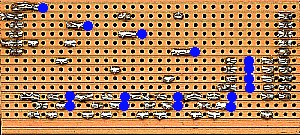

![]() The

jumper J1 can be used to feed the motor from the 5V supply, and this should

be fine just for experimenting, but the motors are designed for 12V, and

won't produce much power from 5V - by disconnecting J1 you can feed a 12V

supply to the top of D5, D6, D7 and D8 - obviously if you don't disconnect

J1 you are very likely to fry the PIC!.

The

jumper J1 can be used to feed the motor from the 5V supply, and this should

be fine just for experimenting, but the motors are designed for 12V, and

won't produce much power from 5V - by disconnecting J1 you can feed a 12V

supply to the top of D5, D6, D7 and D8 - obviously if you don't disconnect

J1 you are very likely to fry the PIC!.

|

|

|

|